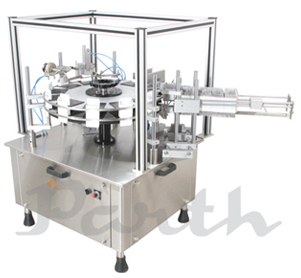

DESCRIPTION:

High Speed Linear Bottle Washing Machine is most ideal for Round and Flat Bottles and finds wide application in PHARMA, FOOD & BEVERAGES INDUSTRIES. The automatic loading arrangement facilities loading of bottles on to SS wire mesh conveyor through feed conveyor or bottles are pushed manually from feed table. This round bottle washing machine or flat bottle washing machine saves manpower as bottles are feed into pockets automatically. The automatic unloading mechanism consists of unloading bottle continues on to Turn Table (Optional).

OPERATION:

Three-cycle rinsing allows flexibilities of various wash cycles such as fresh water, dematerialised water etc. as per the rinsing requirement of bottle. All the pumps are made of SS and all the water contact parts are made of SS 316 on a heavy base of MS structure.

In tunnel design of the bottle washing machine is such that separation is maintained between feeding zone and discharge zone of the cleaned containers. All the mechanical drives are separated and isolated from the washing zone. Approved materials only are used for construction, together with a careful choice of components, thereby taking in to consideration all aspects of sanitation and consequence complying with the pharmaceutical G.M.P. requirements.

The quality of rinsing is ensured through 5 sets of inner and 2 sets of outer nozzles accurately placed to direct the jet at centre of the bottle and the bottle comes out with water totally drained with minimum droplets of water

Parth Engineers & consultant

Gold Member

Gold Member

Audited Supplier

Audited Supplier

Diamond Member

Diamond Member Audited Supplier

Audited Supplier

Gold Member

Gold Member

Audited Supplier

Audited Supplier